with the latest technology

The Széchenyi István University pays special attention to contribute in an innovative way to novel solutions of industry and to the answers to transport challenges. Thanks to an EU project, the institution’s road construction laboratory has recently been equipped with state-of-the-art equipment, which will expand the range of services provided to corporate partners and allow for further improvement of the quality of training.

The Centre for Higher Education and Industrial Cooperation of Széchenyi István University supports the development of the economy by promoting long-term and sustainable business-service-university partnerships that increase the competitiveness of the region. „This was also the aim of the GINOP-2.3.4-15-2020-00009 project, worth more than HUF 2 billion 251 million, which involved the expansion of research, development and innovation capacity at the Győr campus and the Zalaegerszeg automotive test track, which can serve industrial partners. The equipment procured under the project will support, among other things, innovative solutions for the automotive industry and the creation of services related to the development of self-driving mobility,” said Nóra Mészáros, Head of the Directorate of Projects at Széchenyi István University.

The Road Construction Laboratory of Széchenyi István University is equipped with the latest technology (Photo: András Adorján)

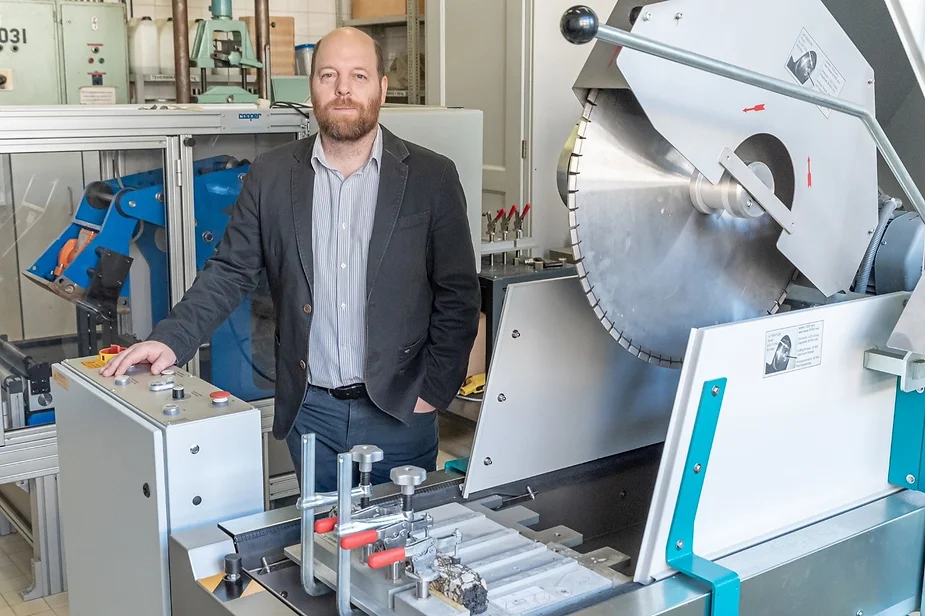

Direct physical inspection of the pavement and the development of related competences are essential for the creation of an autonomous transport environment. To this end, the project has significantly improved the equipment of the institution’s Road Construction and Geodetic Laboratories. „This is a very important development, as the purchase of the equipment will help us to provide our industrial partners with a wider range of high-quality services, to raise the level of our research activities and to integrate this into our training. A state-of-the-art laboratory environment will support all three areas, helping to develop new business partnerships, produce high quality publications and expand our laboratory services.”– said Dr János Szép, Dean of the Faculty of Architecture, Civil Engineering and Transport Sciences of the University. He thanked the university’s management for the support that made the development possible, and the staff of the Directorate of Projects, the faculty and the laboratory for their work in making the project a success.

This nationally rare road surface inspection device is mounted on a vehicle and measures the surface properties of the road surface using a laser while driving. (Photo: András Adorján)

„The biggest attraction is an RSP (Road Surface Profilometer), as there has only been one in the country so far. The instrument, mounted on the front of a vehicle, uses twenty-one lasers to measure various surface geometries while driving. The instrument can contribute to the training of high quality professionals and the launch of new research, while also broadening the range of industrial contacts and laboratory services.”- said Richard Nagy, Head of the Road Construction Laboratory.

Richárd Nagy, head of the Road Construction Laboratory of Széchenyi István University in front of a newly installed cutting machine (Photo: András Adorján)

The laboratory has also been equipped with a 3D machine control system, which is increasingly used in road construction, and which allows the latest technology in civil engineering to be used in the institution. The project also included the purchase of the necessary space scanner, which enables the professionals to digitise the built environment. „As the use of these tools requires both civil engineering and geodetic expertise, we plan to build on our new tools and existing knowledge to launch BIM – 3D Machine Design, a unique training course in the country. The developed material would also serve to enhance the skills of professionals already working in the industry with a degree. This will also increase our research capabilities, aiming to simplify and automate 3D machine control procedures.”

– he stressed.

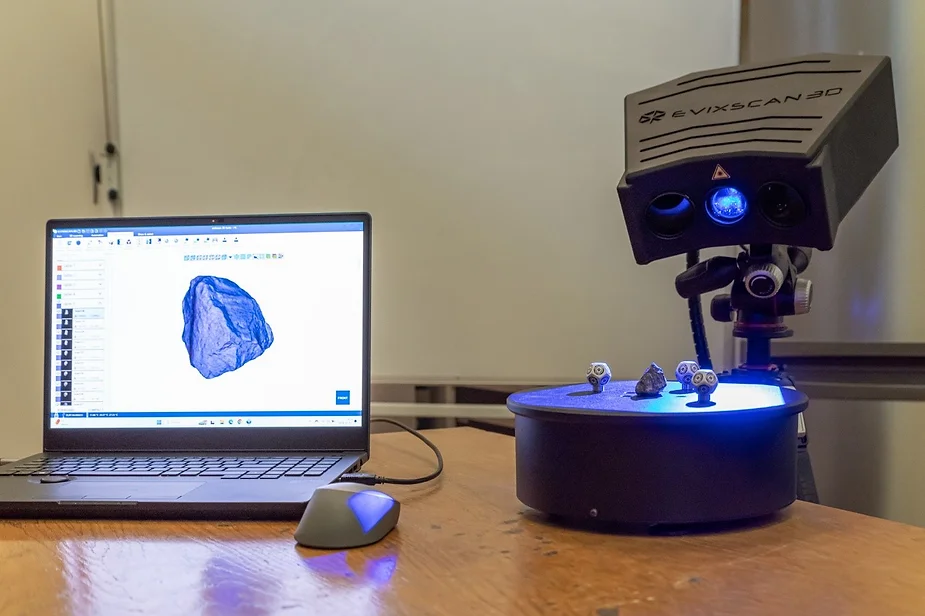

A laser scanner that allows non-destructive testing is usually not standard equipment in a road laboratory (Photo: András Adorján)

Two newly acquired high-precision scanners will also be used to demonstrate non-destructive testing techniques, providing an opportunity for research collaboration between the Departments of Civil and Hydraulic Engineering and Structural and Geotechnical Engineering.

„One of the instruments will allow us to effectively study the macro- and micro-precision of the road surface, to create a material model, through which we plan to publish jointly. The other one is suitable to look at the behaviour of the scanned stone, its fracture behaviour under certain loads. The studies related to the purchased equipment will significantly enhance the skills of our students, contributing to the acquisition of knowledge in demand on the labour market.”- he said.

In addition to state-of-the-art technology, the laboratory also received classic road testing equipment, including an asphalt mixer, asphalt analyser, tyre pressure tester, utility detection equipment, bitumen tester and various cleaning tools.