Created: 2025.11.18. 10:40

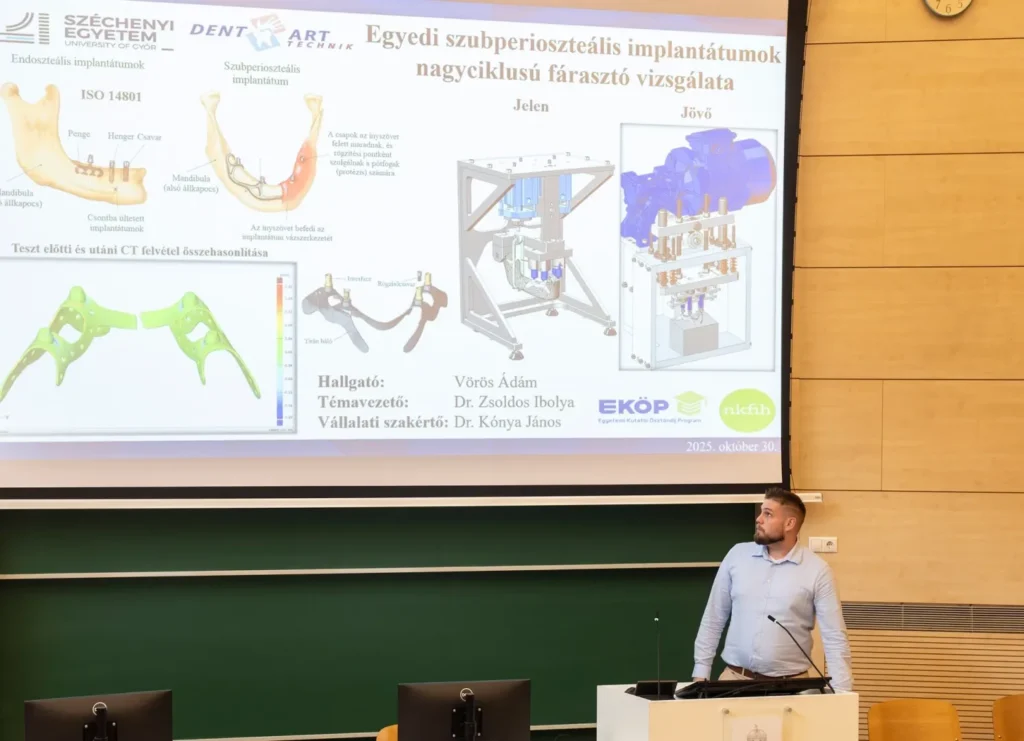

Ádám Vörös, a student of the Doctoral School of Multidisciplinary Engineering Sciences at Széchenyi István University, achieved second place at the prestigious 3MT competition with his research in health technology. The Cooperative Doctoral Programme scholarship holder conducts his PhD research both at the University and at the dental technology company DentArt Technik, focusing on the testing and further development of titanium implants.

For several years, PhD students of Széchenyi István University have had the opportunity to join the Cooperative Doctoral Programme, supported by the Ministry of Culture and Innovation and the National Research, Development and Innovation Office (NKFIH). Participants pursue their studies alongside an industrial career. A national conference for students of the programme was held recently for the second time, where representatives of universities, companies, the Ministry and the NKFIH shared their experiences.

The event included the 3MT competition — short for Three-Minute Thesis — where young researchers had three minutes to present their scientific results to a professional jury. Ádám Vörös, a student of the University’s Doctoral School of Multidisciplinary Engineering Sciences, won joint second place with his research on dental implants, under the supervision of Professor Ibolya Zsoldos.

“Last year I found this unique format fascinating and wanted to see if I could summarise my entire research in three minutes. I was delighted to have the opportunity to test myself and present my work conducted both at the University and at DentArt Technik. It was a particular joy to achieve second place in such a dynamic and challenging environment,” said the doctoral student. He added that he also attended several inspiring presentations on health technology innovations during the conference.

The young researcher focuses on testing implants, specifically subperiosteal implants, which are placed on top of the jawbone and fixed with small screws rather than drilled into it. Vörös highlighted that these titanium devices — unlike single-tooth versions — are entirely custom-made, so neither their testing nor their clinical application has yet been standardised. “With the instruments available in the University’s Material Testing Laboratories — such as the chewing simulator test rig or the CT scanner — we are working to standardise both the process and the requirements for customised devices, ensuring their full safety for widespread clinical use,” he explained. He emphasised that the company’s support is invaluable, as it produces the necessary implants using metal 3D printing, while the expertise and guidance of company specialist Dr János Kónya have also greatly contributed to his progress.

“Our goal is to create a test rig capable of simulating several million chewing cycles in a single day, thereby speeding up the testing process. Each year, we refine the design of currently available implants to develop more optimal structures with improved load resistance. In addition, we examine how to reduce the amount of material used while maintaining adequate mechanical stimulation of the bone, avoiding bone tissue degradation caused by underloading,” detailed the PhD student, who has also taken on teaching duties at the Department of Materials Engineering and Machine Design at Széchenyi István University since the start of the current academic year. Vörös stressed that he owes a great deal to the University, his department, his supervisor, the company expert and the Cooperative Doctoral Programme, which together make it possible for him to pursue scientific research, gain industrial experience, and continuously feed the results back into innovative product development.